Safety, Articles

Why Refineries Spend $250K–$500K on Scaffolding

%20v2.png)

📚 Table of Contents

Introduction

Temporary scaffolding is still the go-to access solution for industrial inspection and maintenance. But for many refineries, it’s also an overlooked drain on operating budgets—with costs ranging from $250,000 to $500,000 per year, sometimes just to support a single unit.

Let’s explore why those numbers are so common (and often underestimated), what drives costs higher on the Gulf Coast, and how robotic inspection technologies are helping operators streamline asset maintenance and reduce unnecessary spend.

One Unit. One Project. $250K+ in Spend.

In one real-world example from a refinery pipe rack project in the UAE, Al Hassan Engineering's contracted scaffolding services for:

-

15,000 cubic meters of tower scaffold

-

Erection/dismantling cost: AED 390,750 (~$106K USD)

-

10-month rental cost: AED 541,687 (~$147K USD)

-

Total: AED 932,437.50 (~$254K USD)

And that’s for one scaffold—on one section of pipe. Whether in the Middle East or the U.S., the underlying cost structure is similar: volume-based rental, high hourly labor rates, long dwell times, and limited reusability.

Breaking Down the Cost of Traditional Access

Refineries typically pay for scaffolding in four ways:

-

Setup/teardown labor, often billed hourly at $65–$75 on the U.S. Gulf Coast

-

Monthly rental of scaffold materials, often priced per cubic meter

-

Recurring inspections and safety modifications

-

Production delays due to scaffold access scheduling

Industry sources like BIC Magazine report that scaffold rental and labor can comprise hundreds of thousands of dollars per unit annually, and up to 20% of total field labor on large projects.

Why Gulf Coast Refineries Spend Even More

In the U.S. Gulf Coast, refineries regularly spend $250K–$500K per year per unit on scaffolding, especially where:

-

Piping is insulated and requires access through multiple layers

-

Dense vertical structures like towers or pipe racks complicate access

-

Scaffold rebuilds are frequent due to shifting inspection scopes

In these environments, traditional access methods actively work against the goal to reduce turnaround time or optimize workflows. Costs build, delays mount, and risk exposure increases.

The ROI of Robotic Inspection

This is where robotic inspection delivers immediate value.

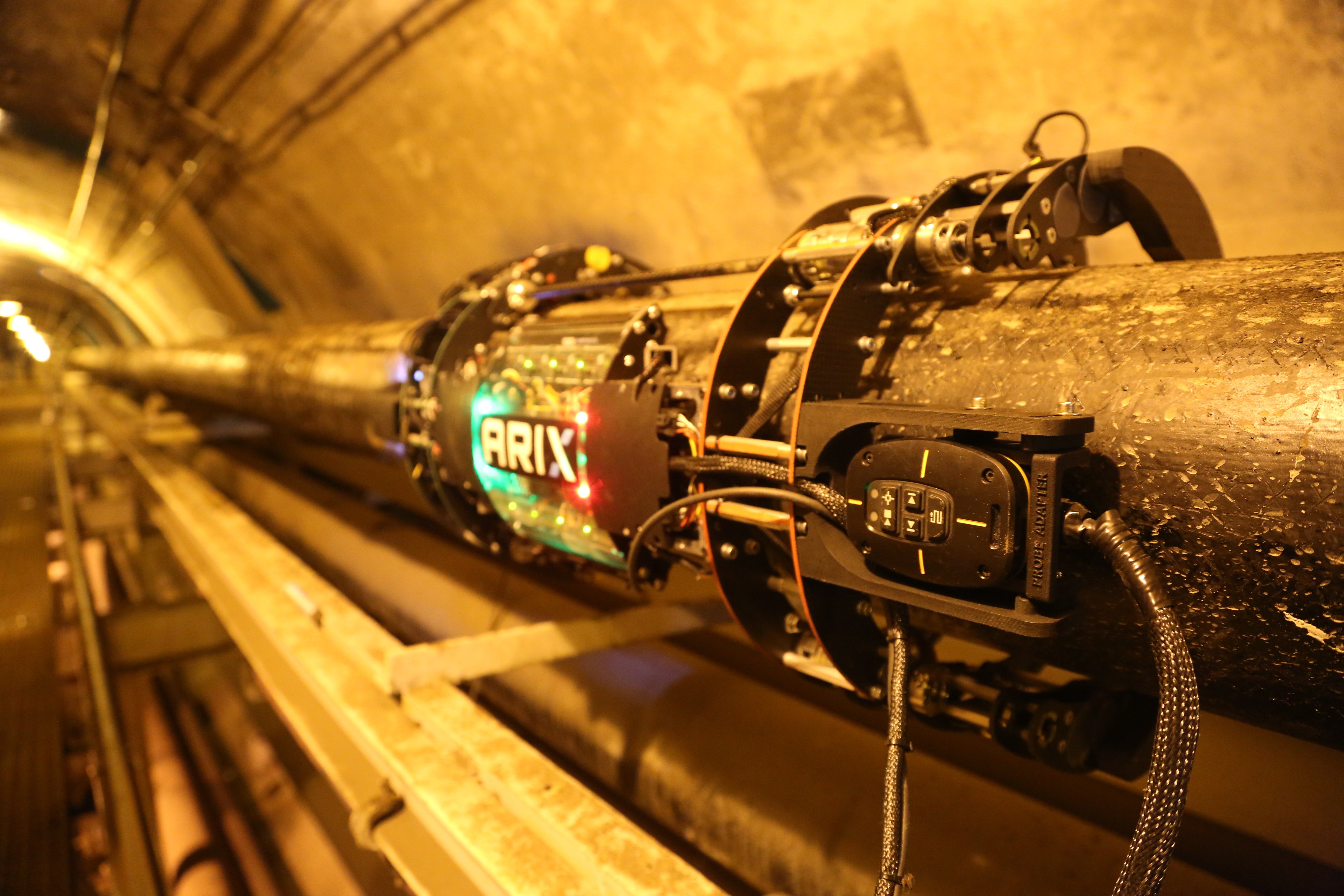

ARIX Technologies robotic systems allow inspectors to safely access above-ground piping—no scaffolding, no insulation removal, no elevated work permits. This unlocks a fast-track path to:

-

Reduce cost of CUI detection

-

Capture inspection data 15x faster

-

Lower total inspection costs by up to 70%

-

Reduce risk and free up skilled labor

-

Optimize inspection workflows across your facility

In short: Robotic inspection ROI is clear when scaffold spend is even partially replaced by faster, smarter, autonomous access.

Let’s Do the Math

If you're spending $300K on scaffolding annually for a single unit, imagine:

-

Eliminating that for even two or three units

-

Saving $1M+ over 3–5 years

-

Applying that budget toward proactive planning, digital inspection records, or AI-driven corrosion modeling

-

Drastically reducing worker exposure and job site congestion

That’s not just a tech investment. That’s an operational unlock.

🔹 Frequently Asked Questions (FAQs)

1️⃣ How much does scaffolding cost for refinery inspections?

Answer: Refineries typically spend between $250,000 and $500,000 per year per unit on scaffolding, depending on complexity, height, and inspection needs.

2️⃣ What’s the most effective way to reduce refinery scaffolding costs?

Answer: Robotic inspection systems eliminate the need for scaffolding in many CUI scenarios, cutting inspection costs by up to 70% while improving speed and safety.

3️⃣ Can insulated pipes be inspected without removing the insulation?

Answer: Yes. Technologies like Pulsed Eddy Current (PEC) allow robotic systems to scan through insulation and jackets, delivering full-surface data with no teardown.

4️⃣ Why are scaffolding costs higher on the Gulf Coast?

Answer: Gulf Coast refineries often have complex vertical structures and higher labor rates, with scaffold erection labor averaging $65–$75/hour, inflating total costs.

5️⃣ What is the ROI of using robotic CUI inspection over traditional methods?

Answer: Robotic inspection is 15x faster and can save refineries $400K+ per unit by removing scaffolding, shortening inspection time, and minimizing operational disruption.

Cost estimates for refinery scaffolding are supported by Al Hassan Engineering’s scaffolding project breakdown, which detailed over $250,000 USD in access costs for a single unit. Industry-wide benchmarks are cited from BIC Magazine’s article on improving scaffold management, highlighting $250K–$500K annual spend per refinery unit. Scaffold labor rate ranges were referenced from BilJax’s scaffold rental pricing guide, and additional field labor insights were informed by the Scaffold & Access Industry Association (SAIA). Robotic inspection ROI figures and cost savings are drawn from ARIX Technologies’ internal deployments and client case studies.

The information provided on this page is for informational purposes only and should not be considered a substitute for professional engineering, inspection, or regulatory compliance advice. While we strive to ensure the accuracy and timeliness of the content, ARIX Technologies makes no guarantees regarding completeness, correctness, or applicability to specific circumstances.

Industry standards and inspection practices may evolve. Always consult certified professionals and regulatory sources for current requirements. ARIX Technologies assumes no liability for decisions based on this content.

Related Resources

Press, Articles

ARIX Technologies Expands into the GCC with 01Lab Partnership

ARIX Technologies Expands into GCC with 01Lab Partnership

Press, Articles

New Algorithm Enhances PEC Accuracy in High-Voltage Inspections

ARIX's Petter Wehlin co-authors study on algorithm eliminating EMI in pipe inspections, reducing false positives in high-voltage environments.

.png)

Safety, Articles

API 570 & CUI: Guide to Piping Inspection & Corrosion Prevention

Learn about API 570 in-service piping inspection, repairs, and CUI (Corrosion Under Insulation) prevention. Explore advanced robotic inspection solutions!

Get in touch with us!

Want innovative solutions to increase safety, lower costs, and preserve your equipment for years to come?

Let’s Talk